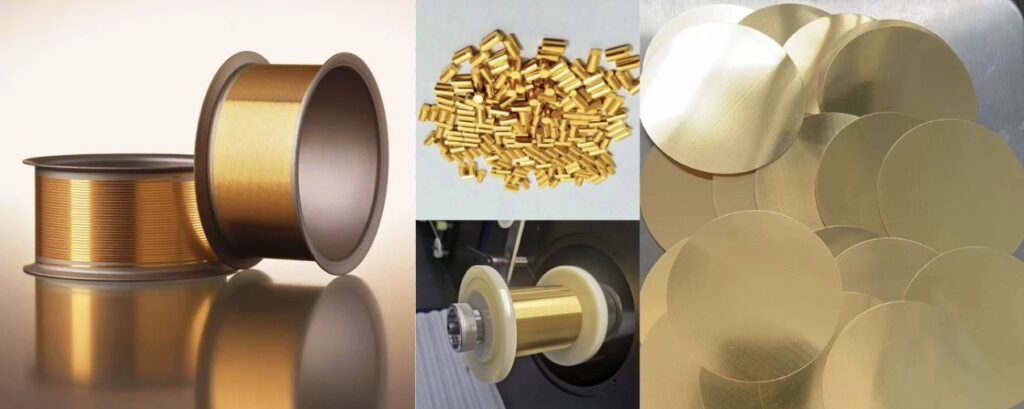

Precious Metal Wire, Strip, Rod & Foil

As a leader in China’s precious metals manufacturing industry, Vision Technology Group offers customized manufacturing services for precious metal wires, fine wires, rods and strips. As one of the foremost manufacturers in this field in China, we have strong capabilities to provide top-quality products at fair and competitive prices to meet your needs. Our services include casting, molding and winding, with capabilities for various diameters and thicknesses. Gold, platinum and palladium alloys can be used for wires, strips, cut pieces or rods in different diameters and thicknesses. By combining our metallurgical expertise with advanced manufacturing systems, our customized precious metal wires have set industry benchmarks for quality and performance. Applied in millions of devices globally, including aerospace, automotive, electric vehicles, medical devices, semiconductor testing, industrial manufacturing, power generation and renewable energy.

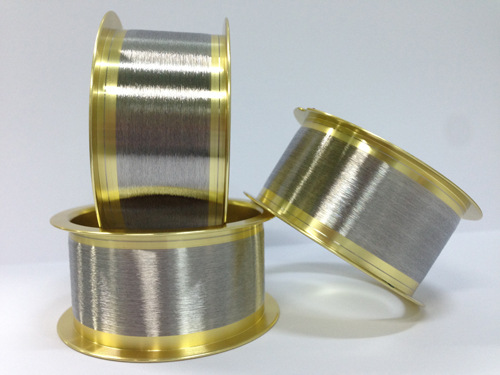

Wire

Customary Metric

Diameter. 0.015mm – 2.0mm

Length Per customer specification

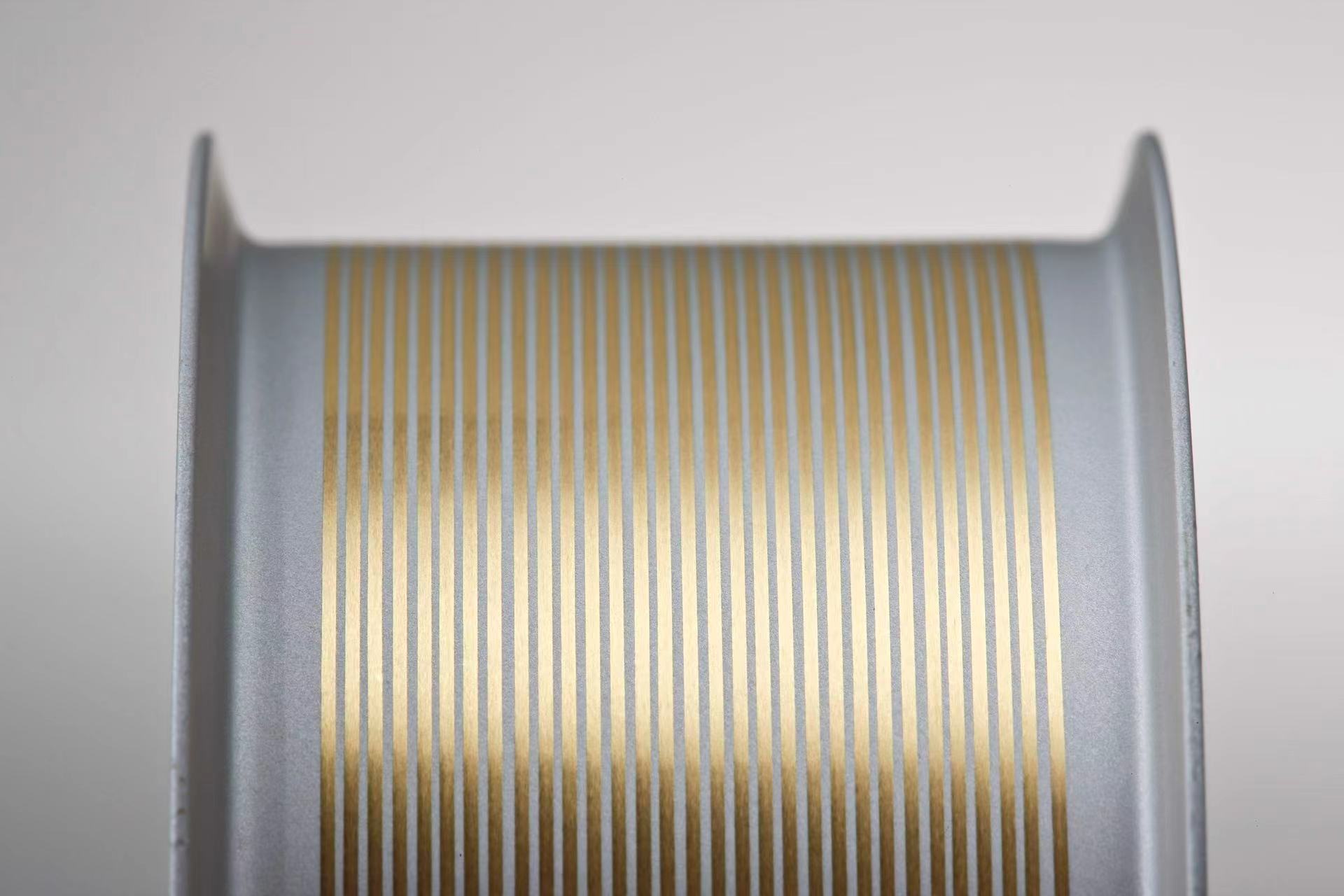

Strip

Customary

Metric

Thickness

Width

Length

<10.16cm

0.005 – 0.05 cm

Per customer specification

Rod

Customary Metric

Diameter. 1.0mm up

Length Up to 100 cm

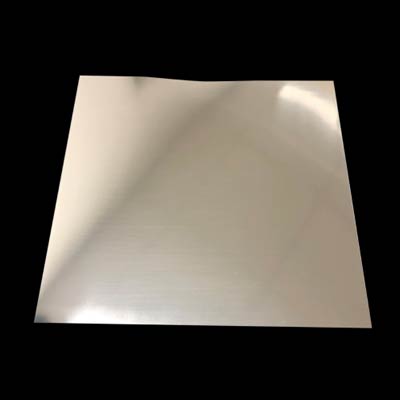

Foil

Foils offer a flexibility other formed products cannot provide. The Deriney Foil is manufactured to meet world class standards in semiconductor and medical applications. These foils are manufactured from the same alloys designed and casted at Deringer-Ney. As for performance, you can expect similar physical and mechanical properties as in wire forms. With thicknesses ranging from 16µm and higher, use for these foils can be found in probe cards, neuro stimulator stints, sensors and industrial applications

Customary

Metric

Thickness

Width

Length

30µm – 2mm

10 cm

Per Customer Specifications